Discover a professional 3D printing powder supplier

Compound Chemicals

Engineering plastic transparent TPU granules pellets different hardness for 3D printing and injection moulding

TPU Granules Thermoplastic Polyurethane Cost-effective TPU Raw Material for 3D Printing

Polyamide 12 resin of nylon 12 per kg 3D printing carbon fiber reinforced CF30% PA12 granules

CAS 26100-51-6 3D Printing pellets market polylactic acid PLA

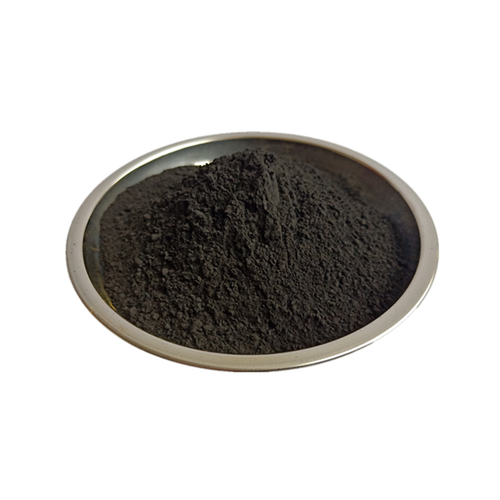

Hot material of the year!! Ultem PEI MILLED POWDER 42 Micron for film spraying/electrostatic spraying or 3D printing

Colour masterbatch abs compound plastic masterbatch for filament 3D printing PLA

PLA Compound Masterbatch 3D Printing Filament

TPU Granules Thermoplastic Polyurethane Cost-effective TPU Raw Material for 3D Printing

TPU Granules Thermoplastic Polyurethane Cost-effective TPU Raw Material for 3D Printing

PETG ABS TPU PLA Raw Materials 3D Printing Filament

TPU Granules Thermoplastic Polyurethane Cost-effective TPU Raw Material for 3D Printing

ABS Plus 3D Printing Filament eABS 1KG for 3d filament the most ing product

Introduction to 3D printing composite materials

3D printing composite materials are advanced materials that combine two or more materials (such as polymers, metals, ceramics, carbon fibers, etc.) through additive manufacturing technology. They have the excellent performance of each component and are widely used in aerospace, medical, automotive and other fields.

Characteristics of 3D printing composite materials

Lightweight: Combination of high strength and low density, suitable for weight reduction scenarios.

High strength: Fiber/nanoparticle reinforcement improves mechanical properties.

Design freedom: Integrated molding of complex structures breaks through traditional manufacturing limitations.

Functional customization: Conductive and high temperature resistance are achieved through material combination.

Low-cost rapid prototyping: Reduce mold requirements and accelerate product development.

Specifications table of 3D printing composite materials

| Parameter | Value Range | Unit |

|---|---|---|

| Tensile Strength | 50–500 | MPa |

| Density | 1.1–4.5 | g/cm³ |

| Layer Thickness | 0.05–0.3 | mm |

| Printing Temperature | 180–400 | °C |

| Fiber Content | 10–60 | % |

Application of 3D printing composite materials

Aerospace: Lightweight components (such as drone frames, satellite parts).

Medical: Customized prostheses, biocompatible implants.

Automotive: High-strength structural parts, thermal management components.

Electronics: Flexible circuits, heat dissipation materials.

Energy: Battery electrodes, lightweight wind turbine blades.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs

Q: What are the common types of 3D printed composite materials?

A: Carbon fiber reinforced plastics, glass fiber composites, metal-ceramic hybrid materials, etc.

Q: What are the advantages compared with traditional manufacturing?

A: Reduce material waste, support complex geometric shapes, and shorten production cycles.

Q: Is it suitable for mass production?

A: Currently more suitable for small batch customization, but high-speed 3D printing technology is promoting large-scale applications.

Q: How to ensure the interlayer bonding strength?

A: Optimize printing parameters (such as temperature, speed) or use interface enhancement technology.

Q: Which 3D printing technologies are compatible with composite materials?

A: FDM (fused deposition modeling), SLS (selective laser sintering), DLP (digital light processing), etc.